HEATPULSE 610 RAPID THERMAL ANNEALER

Additional figures are at the end of this

article.

- SAFETY

- Toxic arsenic vapor is generated by heating of GaAs.

- Internal chamber components can be extremely hot.

- DO NOT OPERATE ABOVE 800º.

- STARTUP

- Startup executable = C:\AG\PCAT.EXE

- RTA Panel : POWER switch "OFF".

- Computer : "ON".

- Open manual valve on wall to start nitrogen.

- Open manual valve on wall to start forming gas (20% H2 in N2).

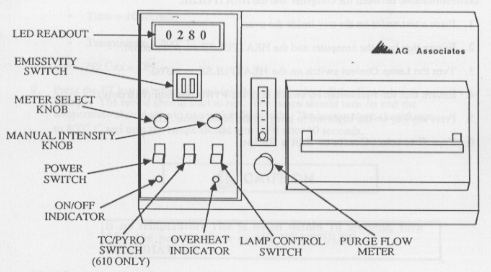

- RTA Panel : Set the PURGE FLOWMETER (20 % H2 in N2) to 20.

- RTA Panel : Set METER SELECT switch to "TEMP".

- RTA Panel : Set PYRO/TC switch to "TC".

- RTA Panel : Set LAMP CONTROL switch to "AUTO".

- RTA Chamber : Load clean sample(s) on silicon support wafer.

- RTA Chamber : Purge with process gasses for 3+ minutes before starting the process recipe.

- RTA Panel : POWER switch "ON". Contactor engagement produces a strong clunk-like sound.

- SPECIFY CONTROL SOFTWARE RECIPE

- Computer : "READ RECIPE".

- Computer : "EXECUTE RECIPE".

- Computer : Check the Steady State (SS), Ramp, and Delay (Dly) parameters.

- RUN THE PROCESS

- Computer : "RUN RECIPE".

- Computer : Monitor process, noting temperature over/under shoots and any other problems in the RTA logbook. Every run must be entered into the logbook.

- At the end of process, continue purging with gasses to evacuate toxic gasses before opening the chamber door.

- Wait until the temperature cools to 100oC before opening the chamber door.

- With the door fully open, wait until the temperature is below 70oC before unloading the sample(s).

- SHUTDOWN

- RTA Panel : POWER switch "OFF".

- Close manual valve on wall to stop forming gas (H2 in N2).

- Close manual valve on wall to stop nitrogen.

- NOTES

- Disregard decimal in the front panel LED meter.

- Emissivity switch (thumbwheels) are for PYRO temperature control mode, not TC mode.

- Password for editing processes is "AGA".

- Please do not operate above 800º.

Example recipe parameter file for Au/Ge alloying:

ACTION TIME sec TEMP C N2 Ar/H2

------ -------- ------- -- -----

Dly 10 0 ON ON

Ramp 10 300 ON ON

SS 60 300 ON ON

Ramp 10 400 ON ON

SS 40 400 ON ON

Ramp 50 50 ON ON

Dly 120 0 ON ON